Foundry & industrial processing Machinery EQUIPMENT & SYSTEMS

U.S. & Canada Call 1.800.457.5456

News

Home News

Simple Solutions That Work!™

HIGHLY TECHNICAL TOOLBOX

Issue 20, Spring 2024

The articles in this edition detail important toolbox reference materials for the latest metalcasting technologies including digital integration, real-time data collection, and the transformative impact of artificial intelligence on the foundry floor—and everything in between—such as compacting, conveying, testing, and important equipment calibrations. Palmer, MMEI, Acetarc, EMI, Klein Palmer, Finite Solutions, The Schaefer Group, Simpson, Wheelabrator, Monitizer, CMH Hall, Industrial Innovations, Molders World, United Erie, D&S Consulting and New England Foundry Technologies provided metalcasting solutions for this issue. This issue includes our special feature: Women in the Foundry.

View this edition of Simple Solutions That Work!

View as PDF.

Sign Up to receive Simple Solutions That Work!

Simple Solutions That Work!

Just like the publication Simple Solutions That Work!

this e-series places an emphasis on solutions you can use—today.

Proven Industrial loT Solution to Optimize Production

Plug Flo Pneumatic Transporter

America's Top Continuous Sand Mixer

Custom Aluminum Furnace Systems

Save with Remanufactured Machines

Quality Foundry Ladles

Simple Solutions That Work!

Just like the publication Simple Solutions That Work!

this e-series places an emphasis on solutions you can use—today.

Custom Designed Furnaces and Systems

America's Top Continuous Sand Mixer

Plug Flo Pneumatic Transporter

Save with Remanufactured Machines

Proven Industrial loT Solution to Optimize Production

Quality Foundry Ladles

Simple Solutions That Work!

Just like the publication Simple Solutions That Work!

this e-series places an emphasis on solutions you can use—today.

Palmer Manufacturing & Supply, Inc.

Sand Reclamation Systems

The SDAM is a shakeout deck with an integral attrition mill to reclaim and reuse sand. The deck is low-level and requires no pit, making for a safer operation.

Reduces molds and lumps to grain size. Five sizes are available. Deck loads to 25,000 lb. Easy clean-out doors

CMH Manufacturing

Robotic-Ready Tilt-Pour Machines

Our Tilt-Pour machines, designed for seamless robotic interface, ensure reduced turbulence and optimal molten metal flow.

Achieve tighter, harder castings with efficient cycle times.

Accommodate molds up to 13,000 lbs.

The Schaefer Group, Inc.

High Perfomance Stack Melters

Designed for melting scrap/ingot/chips, degassing/filtration, and more.

Partnered with Sanken Sangyo, inventor and global leader of the Stack Melter.

Ranging from small in-cell melters from 6001bs/hr to large central melt furnaces up to 15,000lbs/hr.

Klein Palmer

Plug Flo Pneumatic Transporter

Plug Flo system transports sand through pipelines with little sand degradation.

- 45% reduced compressed air compared to "Dilute Phase" conveyors

- Low Energy/ Low Compression Air Usag

- Reduces labor, operation, and maintenance costs

Acetarc

Quality Foundry Ladles

Ladles designed to your specific requirements and engineered to provide years of reliable service.

- Motor drive or manual gearbox

- Lip pour

- Teapot spout

- Bottom pour

- Safe-pour powered bottom pour

- Ladle pre-heaters & dryers

MESH

Digitalizing Metal Manufacturing

An affordable solution to increase efficiency and streamline operations

- Global sourcing database of 2700+ suppliers

- Digital RFQ to eliminate spreadsheets

- Supplier relationship management

- Quality management with APQP, Incident Reporting, and NPD

- Supplier profiles are free to create

Simple Solutions That Work!™

COMMUNICATIONS

Issue 19, Fall 2023

Communicating effectively is an art form. Many times, a customer needs to ‘see it’ to believe in it. Some prefer a 3D drawing whereas others prefer experiencing it in actual production. There are many ways to ensure the customers’ needs are articulated and documented and our participants in today’s issue will detail the many ways to ensure what customers value and expect are understood. Palmer, MMEI, Acetarc, EMI, Klein Palmer, Finite Solutions, The Schaefer Group, Simpson, Wheelabrator, Monitizer, Mesh Works, CMH Hall, Industrial Innovations, BHS Robotics, Cast Metals Federation, and D&S Consulting provided solutions for this issue.

View this edition of Simple Solutions That Work!

View as PDF.

Sign Up to receive Simple Solutions That Work!

Big Savings on Palmer's Best-Selling Equipment

Save 10% Now!

The time is now to upgrade equipment that is costing your foundry expensive downtime and maintenance issues. Palmer equipment installs quickly, operates more efficiently, and lasts longer-making high quality castings at less cost has never been more affordable!

The following Palmer standard equipment (with standard options) is 10% off

- Sand Heaters

- Compaction Tables

- Bucket Elevators

- Powder Feeders

- Continuous Sand Mixers: M200 & MlOO sizes only

Hurry... this hot summer sale ends 7.31.23

ORDER NOW

Purchase order must be received June 27, 2023 - July 31, 2023. Cannot be combined with other offers. No adjustments to prior purchases. Any standard options must be for the qualifying equipment and ordered at the same time to receive the discount.

Simple Solutions That Work!

Just like the publication Simple Solutions That Work!

this e-series places an emphasis on solutions you can use—today.

The Schaefer Group, Inc.

High Performance Stack (Tower) Melter

- Reduce Metal Lost - 98% yields.

- Simple operation and ease of maintenance.

- Compact footprint - V3 of conventional space.

- Reduce Energy - savings up to 259'.

- Environmentally friendly - less exhaust, chips and scattering.

Palmer Manufacturing & Supply, Inc.

Featured Equipment:

- No-Bake Semi-Automated Molding Systems: Universal & Flip Molding

- Thermal & Mechanical Sand Reclamation Systems

- 3X Higher Productivity, Up to 20 Molds/HR with One Operator!

Klein Palmer

Plug Flo® Pneumatic Transporter

Plug Flo® system transports sand through pipelines with little sand degradation.

- 459% reduced compressed air compared to "Dense Phase· conveyors

- Low Energy/ Low Compression Air Usage

- Reduces labor. operational. and maintenance costs

CMH Manufacturing

REVOLUTIONARY.

GREEN.

Introducing a revolutionary eco-conscious home of pressure-assisted casting machines featuring oil-free, low-energy, and low-noise operation

EMI

High Performance Matchplate Molding Machines

Designed to deliver consistent mold quality, high production speeds, and maintenance friendly features help keep your investment running smooth.

- Heavy Duty 6-Piece Frame

- Unique Cope Lift

- Innovative Upper Cope Mold Ejection System

- Unique squeeze Head

- Centerally Located HMI

Acetarc

Featured Equipment Foundry Ladles Solid, reliable and enduring For all applications Motor drive or manual gearbox Lip pour Teapot spout Bottom pour Safe-pour powered bottom pour Ladle pre-heaters & dryers Designed and built to your specific requirements

Acetarc is represented by Palmer Manufacturing & Supply in the USA

Visit Palmer in Booth #218 at Metalcasting Congress

AFS Metalcasting Congress

April 25-27, 2023 Cleveland, OH

Simple Solutions That Work!™

HOW TO

Issue 18, Spring 2023

In this issue you will hear from industry professionals sharing newer “How To” methods and technologies on their production floors. This publication began in 2014 with the belief that we could produce a more solution-oriented product with resources that foundries could make use of today. Since that time, our mission has never changed and remains at the core of everything Simple Solutions That Work stands for. No matter which issue you read, there will always be references, solutions, and experiences to help make castings better, faster, and more profitably.

View this edition of Simple Solutions That Work!

View as

Simple Solutions That Work as a PDF.

Sign Up to receive Simple Solutions That Work!

Simple Solutions That Work!

Just like the publication Simple Solutions That Work!

this e-series places an emphasis on solutions you can use—today.

Acetarc

Featured Equipment Foundry Ladles Solid, reliable and enduring For all applications Motor drive or manual gearbox Lip pour Teapot spout Bottom pour Safe-pour powered bottom pour Ladle pre-heaters & dryers Designed and built to your specific requirements

Palmer Manufacturing & Supply, Inc.

Featured Equipment:

- No-Bake Semi-Automated Molding Systems: Universal & Flip Molding

- Thermal & Mechanical Sand Reclamation Systems

- 3X Higher Productivity, Up to 20 Molds/HR with One Operator!

The Schaefer Group, Inc.

Featured Equipment:

Ladle Pre-Heaters Schaefer ladle pre-heaters are designed according to the size of the ladle and the alloy you are heating. Steel requires a higher input versus aluminum.

- Typical burner ratings range: 100,000 BTU to 1,750,000 BTU

- Regulated gas supply: ½ lb to 1 lb

- Air supply required to tilt the burner into the ladle: regulated at 60 psi at 10 cfm

- Power supply: 120V AC @ 30 amps

Learn More:Click here

The Schaefer Group

Featured Equipment:

Ladle Pre-Heaters

Schaefer ladle pre-heaters are designed according to the size of the ladle and the alloy you are heating.

Steel requires a higher input versus aluminum.

- Typical burner ratings range: 100,000BTU's to 1,750,000 BTU's

- Regulated gas supply: ½ lb to 1lb

- Air supply required to tilt the burner into the ladle: regulated at 60 p.s.i. at 10 c.f.m.

- Power supply: 120V AC @ 30 amps

EMI

The most complete range of core machines:

- Cold Box, Shell, Hot Box

- High Production to Jobbing

- Dual Station Designs

- Complete Core Room

- Remanufacturing Options

Also providing: mold machines and handling, sand systems, robotic finishing, and more

Klein Palmer

Featured Equipment:

Statormix® Core Sand Mixing System Advantages:

- Accurate & Reliable Binder Dosing System

- High Core Strength

- Easy to Clean & Maintain

- Reduced Binder Consumption

- Wear Resistance Lining

- Process Partial Batches

- Negligible Sand Residue After Discharge

CMH Manufacturing

Meet the Hall Family of Robotic Friendly Machines

Palmer Manufacturing & Supply Congratulates Innovative Casting Technologies on their 25th Anniversary, and exceptional growth.

We are proud to have served as their no-bake equipment supplier through the years.

In a World of Duplication, This is Innovation

Custom CoreMakers Like No Other!

Blowing CERAMICS

CM25 CoreMaker

- No-Bake or Cold Box

- Gassing Head

- Blow Plates and Gassing Plates

- Gate Assembly between Hopper and Chamber with Level Sensor

RFID

CM50 CoreMaker

- Cold Box Upgrade

- RFID Control System

- Laser Box Alignment Tool

- Dual Shuttle Car System

Blowing Water Soluble Material

CM50 CoreMaker

- Laser Locating Device

- Sliding Platen Table

- Hydraulic Clamping Upgrade (German and English Labeling)

- CO2 Gassing System

C02 Gassing System

CM25 CoreMaker

- 300 lb Hopper / Bin Level Indicator

- Modification to Butterfly Valve Blow Chamber Closure

- Reverse Taper Blow Chamber

- CoreBox Clamping System

- CO2 Gassing System

THANK YOU!

Thank you for visiting us at Fundi Expo 2022 in the Maza booth.

Please email Enrique Mañueco for sales and service of Palmer’s full line of No-Bake equipment in Mexico.

MAZA Insumos, S.A. de C.V.

E-mail: [email protected]

Web: www.maza.com.mx

Simple Solutions That Work!™

BACK TO BASICS

Issue 17, Fall 2022

Our September 2022 edition is our Back To Basics issue. Our line-up features important fundamentals on important processes such as sand storage, aluminum degassing, as well as RFID basics. We delve into teapot ladles, resins, furnace and molding basics and hope these articles serve as references to refer back to, for years to come. This issue features articles from Palmer Manufacturing & Supply, Eagle Alloy, MESH Works, Acetarc, HA-International, EMI, MMEI, CMH Hall, Klein Palmer, Finite Solutions, Porosity Solutions, D and S Consulting, Crown Packaging, and Marketing Options.

View this edition of Simple Solutions That Work!

View as

Simple Solutions That Work as a PDF.

Sign Up to receive Simple Solutions That Work!

Introducing Palmer Technical Sand

If you’re ready to say goodbye to silica sand and hello to increased casting quality with less scrap, Palmer has the product for you.

All foundries are facing increasing regulatory pressure to eliminate silica sand. Palmer Technical Sand (PTS) is spherical ceramic sand that has superior crushing resistance to silica, chromite, and most ceramic sands. The strength of PTS allows for efficient reclamation in mechanical or thermal applications, reducing scrap.

BENEFITS

- Provides superior finish in 3D sand printing applications

- Eliminates veining defects

- Reduces or eliminates gas defects

- Avoids undesirable reactions with different metals and alloys, resins and additives in the casting process

- Offers high strength and thermal stability to cast complex geometric and thin parts

- Creates a low deterioration effect in the reclaimed sand process

- Eliminates health hazards associated with crystalline silica exposure (which meets the new OSHA silica PEL regulations)

USES

- Alloys for heavy engine parts

- Aluminum automotive engine parts

- Carbon steel turbines

- Cast iron valves

- Non-ferrous alloys aircraft parts

- Special non-ferrous alloys for complex and thin wall components

- Stainless steel marine components

Contact us at 937‑323‑6339 to learn more and confirm which product is right for you. Or email us at [email protected].

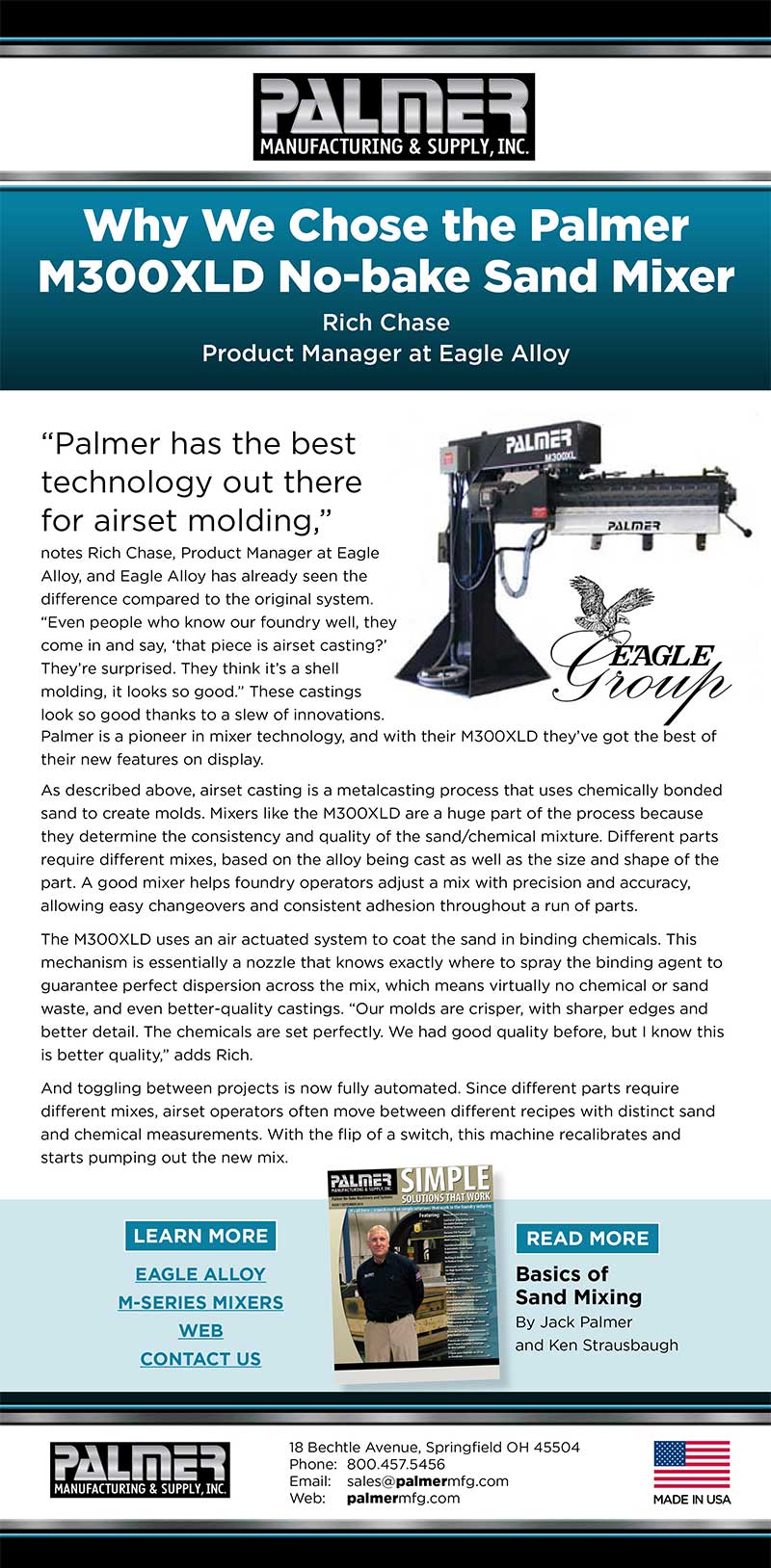

Why We Chose the Palmer M300XLD No-bake Sand Mixer

Rich Chase

Product Manager at Eagle Alloy

"Palmer has the best technology out there for airset molding,"

notes Rich Chase, Product Manager at Eagle Alloy, and Eagle Alloy has already seen the difference compared to the original system. "Even people who know our foundry well, they come in and say, 'that piece is airset casting?' They're surprised. They think it's a shell molding, it looks so good." These castings look so good thanks to a slew of innovations. Palmer is a pioneer in mixer technology, and with their M300XLD they've got the best of their new features on display.

As described above, airset casting is a metalcasting process that uses chemically bonded sand to create molds. Mixers like the M300XLD are a huge part of the process because they determine the consistency and quality of the sand/chemical mixture. Different parts require different mixes, based on the alloy being cast as well as the size and shape of the part. A good mixer helps foundry operators adjust a mix with precision and accuracy, allowing easy changeovers and consistent adhesion throughout a run of parts.

The M300XLD uses an air actuated system to coat the sand in binding chemicals. This mechanism is essentially a nozzle that knows exactly where to spray the binding agent to guarantee perfect dispersion across the mix, which means virtually no chemical or sand waste, and even better-quality castings. "Our molds are crisper, with sharper edges and better detail. The chemicals are set perfectly. We had good quality before, but I know this is better quality," adds Rich.

And toggling between projects is now fully automated. Since different parts require different mixes, airset operators often move between different recipes with distinct sand and chemical measurements. With the flip of a switch, this machine recalibrates and starts pumping out the new mix.

Simple Solutions That Work!™

Flexible Manufacturing & Engineering Trends

Issue 16, Spring 2022

While manufacturing has been tested in the past; nothing compares to the upheaval caused by the pandemic. All of this pointed to known weaknesses in our supply chain along with the many reasons to be using data correctly and having intelligent automated process to rely upon. Palmer Manufacturing & Supply, New England Foundry Tech, Solutions Founderie, Industrial Innovations, HA International, Vibrotech, MMEI, Acetarc, Finite Solutions, CMH Hall, Klein Palmer, EMI, The Schaefer Group, Porosity Solutions, Innovative Casting Technologies, and Trebi Robotics provided flexible manufacturing solutions that you can use today, in this issue.

View this edition of Simple Solutions That Work!

View as

Simple Solutions That Work as a PDF.

Sign Up to receive Simple Solutions That Work!

See Equipment Innovations in Action

NEW 5-Axis CNC Automatic High-Speed Grinder

- Reduces power & air consumption vs manual grinding

- Reduces labor from high-speed grinding and fast part changeovers

- Reduces training time with user-friendly programming

CastExpo demonstration times:

Saturday, Sunday, Monday:

10 AM, 11:30 AM, 1 PM, 2:30 PM, 4 PM

Tuesday: 9:30 AM, 10:45 AM

Flip & Universal Molding Machines

High production No-Bake Molding Systems with low capital costs makes No-Bake molds with a variety of tooling, minimal setup, and minimal tooling modifications— NO ROLLOVER NEEDED!

In addition to the latest in automation technologies, we will be showing the latest in mixing, conveying, degassing, ladling, analyzing and engineering advancements. See it all at the Palmer booth #2341.

Jack Palmer Interview: From foundry rat to industrial choreographer

WYSO | By Tom Stafford

Springfield, Ohio of the 1960s and 70s was an industrial town full of hot, gritty foundries. Jack Palmer, the son of a foundry foreman, knew those dim lit places as well as any foundry rat. In them, he learned the fundamental lessons that now have products with his name – and his father’s – in 27 countries.

At 68, Jack Palmer is as no-nonsense as his work clothes: a long sleeved white shirt and blue jeans under a head of solid white hair.

"I grew up in the foundry," Palmer says. "I started working when I was 14. My main job was always making things or fixing things. Wire, plumb, hydraulic. I knew what worked and I knew what didn’t. I knew what was good and I knew what sucked."

New Palmer CNC Automatic Grinder

Palmer introduces its 5-Axis CNC Automatic Grinder with the same heavy-duty long- lasting design that is a Palmer hallmark.

This automatic high-speed grinder reduces finishing time, which reduces labor costs and injuries. This grinder will perform the work of 3-5 manual grinders, with higher quality that is repeatable. Ideal for grinding/deburring of iron, steel, brass and bronze castings in both jobbing and high production foundries. Two sizes of machines to process castings from a few lb to 1.25 tons.

Benefits

- Reduced floor space due to small footprint

- Reduced power & air consumption vs manual grinding

- Reduced labor from high-speed grinding and fast part changeovers

- Reduced training time with user-friendly programming

Standard Features

- Rotating diamond wheel & diamond pencil tool

- Robotic load/unload option available

- Heavy cast iron base to control vibrations

- Moveable control panel

- Fanuc controls, motors and drives

- Access doors on both sides of machin

- Service and spare parts in the USA

Learn More: Click here

See it in action at CastExpo 2022 Booth #2341

NEW from Palmer Portable Rotary Aluminum Degasser For Higher Quality Aluminum Castings!

Degassing eliminates hydrogen from the molten aluminum and gas porosity from the castings. Porosity free castings equal better mechanical properties, surface finish and profitability.

INDUSTRY LEADING FEATURES

- Eliminates hydrogen porosity in melt & castings

- Anti-vortex shaft design prevents oxides from being sucked into the melt

- For ladles, dip-out furnaces, crucible furnaces with capacity from 50 – 3,000 lb

- Lightweight – 37 lb

- Fast – 5 to 15 minutes depending upon crucible size and melt conditions

- Rugged stainless-steel construction

- Variable speed air-motor driven shaft

- Eliminates use of hazardous degassing tablets and harmful gasses such as chlorine

- Compatible with one piece shaft or two-piece impeller shaft

- Optional fully adjustable leg assembly allows for loading without hoist or stationing over flat top furnace.

Learn More: Click here

From the Palmer Team to yours, Merry Christmas and Happy New Year!

Thank you to our customers, vendors and partners. We appreciate your support and wish you all the best in the holiday season.

Simple Solutions That Work!™

Case Studies

Issue 15, Fall 2021

Our September 2021 edition is all about "Case Studies". Our Case Study issue, one of our most popular topics because—everyone wants to know “how” it was done. This issue covers ‘how it came to fruition and what the results were’. Many of our participants worked very hard to get approvals to release how their engineering solutions increased production or decreased labor through automation, and then the all-important – how quality was enhanced. This Issue features Case Stuies from Palmer, MMEI, Acetarc, EMI, HA International, Finite Solutions, The Schaefer Group, Klein Palmer, Porosity Solutions, New England Foundry Tech, and Marketing Options.

View this edition of Simple Solutions That Work!

View as

Simple Solutions That Work as a PDF.

Sign Up to receive Simple Solutions That Work!

Simple Solutions That Work!

Just like the publication Simple Solutions That Work! this e-series places an emphasis on solutions you can use—today.

Palmer Manufacturing & Supply

Featured Equipment:

- No-Bake Semi-Automated Molding Systems: Universal & Flip Molding

- Thermal & Mechanical Sand Reclamation Systems

- Lunch & Learn Virtual Meetings Click here for topics and schedule

See the UMM in action: Click here

Klein Palmer

Featured Equipment:

Statormix® Core Sand Mixing System

Advantages:

- Accurate & Reliable Binder Dosing System

- High Core Strength

- Easy to Clean & Maintain

- Reduced Binder Consumption

- Wear Resistance Lining

- Process Partial Batches

- Negligible Sand Residue After Discharge

HA International

Featured Technology:

Metal Feeding Technology Powered by Chemex

- Ideal for Complex Castings

- Allows Feeder Place in Previously Inaccessible Locations.

Side Insert Sleeves for Vertical Molding: Click here

The Schaefer Group

Featured Equipment:

Ladle Pre-Heaters

Schaefer ladle pre-heaters are designed according to the size of the ladle and the alloy you are heating.

Steel requires a higher input versus aluminum.

- Typical burner ratings range: 100,000BTU's to 1,750,000 BTU's

- Regulated gas supply: ½ lb to 1lb

- Air supply required to tilt the burner into the ladle: regulated at 60 p.s.i. at 10 c.f.m.

- Power supply: 120V AC @ 30 amps

EMI

Featured Equipment:

- Mold Machines & Mold Handling Equipment

- Core Machines - Cold Box, Shell, Hot-Box

- Automation Solutions - Robotic Finishing

- Foundry Engineering & Design Services

Growing Since 1982: Osborn, SPO, Sutter, Herman, Savelli, & Harrison

Acetarc

Featured Equipment:

- Foundry Ladles – All Applications

- Safe-Pour – Powered Bottom - Pour System

- Ladle Pre-Heater & Pre-Heater/Dryer Units

See Safe-Pour in action: Click Here

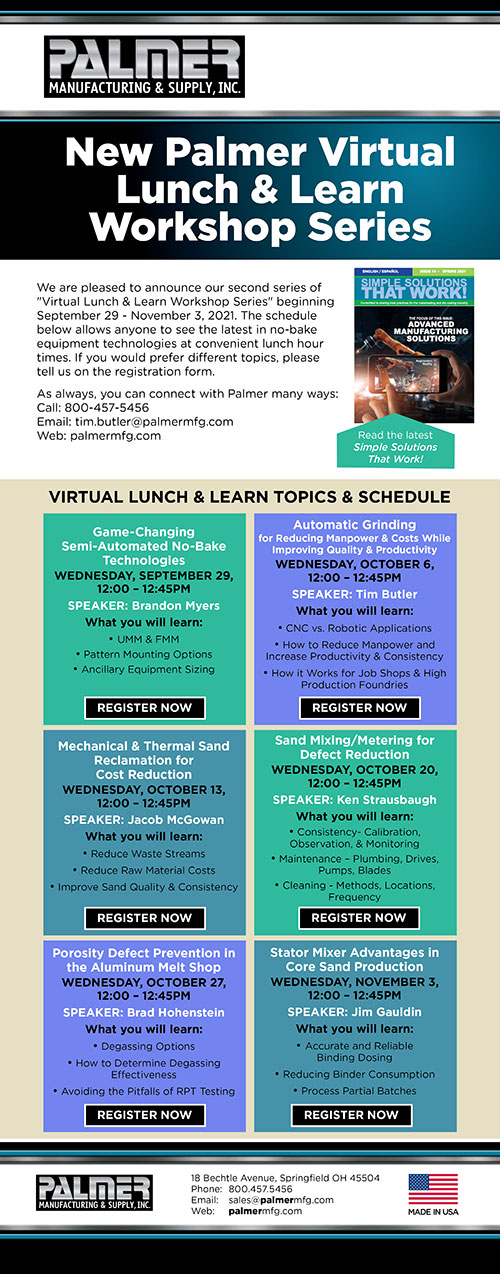

New Palmer Virtual Lunch & Learn Workshop Series

We are pleased to announce our second series of "Virtual Lunch & Learn Workshop Series" beginning September 29 - November 3, 2021. The schedule below allows anyone to see the latest in no-bake equipment technologies at convenient lunch hour times. If you would prefer different topics, please tell us on the registration form.

As always, you can connect with Palmer many ways:

Call: 800-457-5456

Web: palmermfg.com

VIRTUAL LUNCH & LEARN TOPICS & SCHEDULE

Game-Changing Semi-Automated No-Bake Technologies

WEDNESDAY, SEPTEMBER 29,

12:00 – 12:45PM

SPEAKER: Brandon Myers

What you will learn:

- UMM vs FMM

- Pattern Mounting Options

- Ancillary Equipment Sizing

Automatic Grinding for Reducing Manpower & Costs While Improving Quality & Productivity

WEDNESDAY, OCTOBER 6,

12:00 – 12:45PM

What you will learn:

- CNC vs. Robotic Applications

- How to Reduce Manpower and Increase Productivity & Consistency

- How it Works for Job Shops & High Production Foundries

Mechanical & Thermal Sand Reclamation for Cost Reduction

WEDNESDAY, OCTOBER 13,

12:00 – 12:45PM

SPEAKER: Jacob McGowan

What you will learn:

- Reduce waste streams

- Reduce raw material costs

- Improve sand quality & consistency

Sand Mixing/Metering for Defect Reduction

WEDNESDAY, OCTOBER 20,

12:00 – 12:45PM

SPEAKER: Ken Strausbaugh

What you will learn:

- Consistency- Calibration, Observation, & Monitoring

- Maintenance – Plumbing, Drives, Pumps, Blades

- Cleaning - Methods, Locations, Frequency

Porosity Defect Prevention in the Aluminum Melt Shop

WEDNESDAY, OCTOBER 27,

12:00 – 12:45PM

SPEAKER: Brad Hohenstein

What you will learn:

- Degassing options

- How to determine degassing effectiveness

- Avoiding the pitfalls of RPT testing

Stator Mixer Advantages in Core Sand Production

]WEDNESDAY, NOVEMBER 3,

12:00 – 12:45PM

SPEAKER: Jim Gauldin

What you will learn:

- Accurate and Reliable Binding Dosing

- Reducing Binder Consumption

- Process Partial Batches

Palmer M-Series High Speed Continuous Mixers

America's Favorite Sand Mixer!

Palmer proudly supplies the most complete and flexible line of high speed continuous sand mixers available in the world.

- Rugged - heavy-duty construction designed for years of use and abuse with minimal maintenance.

- Simple design - easy to operate/maintain.

- Quick access mixing chamber dual doors. No tools required.

- Tungsten-carbide tipped mixing blades for increased life.

- All Palmer mixers feature as standard magnetically coupled pumps.

- Many options available - mixer can be custom fitted to match the application's exact requirements.

Palmer Preventative Maintenance Program

Quarterly or Semi-Annual

Save 20% on Labor!

Save 20% on Spare Parts!

Schedule quarterly or semi-annual maintenance to save big...and keep your production up and running.

- Labor rate per visit reduced by 20%

- Spare parts used during the time of the work being performed will also be reduced 20%

Spare Parts

Palmer maintains over $3 million in spare parts inventory and services literally thousands of machines globally. Our comprehensive inventory includes:

Pumps, mixer rebuild kits, blades for all mixers, Globe hammers, ball valves, flanges, nozzles, conveyor belts, couplings, motors, driveshafts, augers and more.

During a scheduled preventative maintenance visit, the Palmer Service Team, in addition to offering the discount can also create discounted rebuild mixer kits for all of your Palmer equipment. We can also provide a custom quote tailored to your exact equipment with solutions to keep your foundry running smoothly. Discounts for labor and spare parts only apply when signed up for the Palmer Quarterly or Semi-annual Preventative Maintenance Program in 2021. USA and Canada only.

To schedule the Palmer Service Team or learn more:

Email: [email protected]

Call: 800-457-5456 /1-937-323-6339

Ask for the Service Department

Simple Solutions That Work!™

Advanced Manufacturing Solutions

Issue 14, Spring 2021

Our April 2021 edition is all about "Advanced Manufacturing Solutions." Advanced manufacturing solutions are everywhere on the foundry floor. From 3D printers to high speed automation and everything in between; as you spend time reviewing all of your new options, spend time on how you will maintain, train, upgrade and replace these technologies – especially in difficult times.

Click here to view this edition of Simple Solutions That Work!

Click here to view or download this edition of

Simple Solutions That Work as a PDF.

Have a solution you would like to share? Complete our form! All solutions that are selected for future publication will win $100 Palmer Bucks!

To subscribe to Simple Solutions That Work, click here: sign-up

In a World of Duplication, This is Innovation

Custom CoreMakers Like No Other!

Blowing CERAMICS

CM25 CoreMaker

- No-Bake or Cold Box

- Gassing Head

- Blow Plates and Gassing Plates

- Gate Assembly between Hopper and Chamber with Level Sensor

RFID

CM50 CoreMaker

- Cold Box Upgrade

- RFID Control System

- Laser Box Alignment Tool

- Dual Shuttle Car System

Blowing Water Soluble Material

CM50 CoreMaker

- Laser Locating Device

- Sliding Platen Table

- Hydraulic Clamping Upgrade (German and English Labeling)

- CO2 Gassing System

C02 Gassing System

CM25 CoreMaker

- 300 lb Hopper / Bin Level Indicator

- Modification to Butterfly Valve Blow Chamber Closure

- Reverse Taper Blow Chamber

- CoreBox Clamping System

- CO2 Gassing System

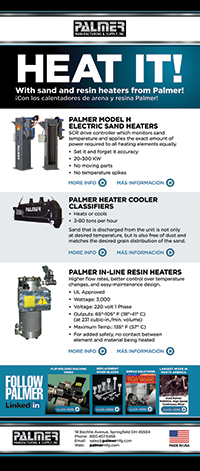

HEAT IT!

With sand and resin heaters from Palmer!

¡Con los calentadores de arena y resina Palmer!

Palmer Model H Electric Sand Heaters

SCR drive controller which monitors sand temperature and applies the exact amount of power required to all heating elements equally.

- Set it and forget it accuracy

- 20-300 KW

- No moving parts

- No temperature spikes

Palmer Heater Cooler Classifiers

- Heats or cools

- 3-80 tons per hour

More Info

Palmer In-Line Resin Heaters

Higher flow rates, better control over temperature changes, and easy-maintenance design.

- UL Approved

- Wattage: 3,000

- Voltage: 220 volt 1 Phase

- Outputs: 65°-105° F (18°-41° C) (at 231 cubic-in./min. volume)

- Maximum Temp.: 135° F (57° C)

- For added safety, no contact between element and material being heated

Palmer Spare Parts Keeps Your Production Up & Running

Palmer maintains over $3 million in spare parts inventory and services literally thousands of machines globally—shipping most parts same day!

Palmer Manufacturing & Supply is the exclusive North & South American stocking distributor of GLOBE Knockout Hammers and replacement spare parts.

More info: HAMMERS

Spare Parts

We stock: Viking pumps, conveyor belts, mixer driveshafts, couplings, elevator head pulleys, elevator tail pulleys, elevator shafts, mixer chambers, Hastalloy pumps, Leeson motors, sprockets, electrical components, bearing flanges, flex hoppers for powder feeders, powder feeder augers, set collars, ball valves, chemical nozzles and much more.

More info: SPARE PARTS

Mixer Rebuild Kits

Palmer provides two levels of rebuild kits for our popular M-Series 50 – 200 Mixers to prevent downtime, with a substantial discount versus purchasing these items individually.

More info: MIXER REBUILD KITS

Pricing & availability

Email: [email protected]

Call: 800-457-5456 (Ask for the Parts Dept.)

Wishing You a Merry Christmas and a Happy New Year!

From all of us at Palmer...

"THANK YOU" to our customers for a wonderful year!

Palmer Manufacturing & Supply, Increases Engineering Staff

Palmer Manufacturing & Supply, Inc., recently announced Jose M. Larrea as Electrical Engineer. J. Larrea is a graduate of Calvin University with a bachelor’s degree in Electrical and Computer Engineering and a minor in business administration. Fluent in Spanish, he will provide additional technical support to Palmer’s growing international expansion in Mexico and South America.

"J. Larrea comes to Palmer with an exceptional international manufacturing background that includes automation and controls experience" said Rick Hartzell, General Manager of Palmer Manufacturing & Supply.

"Palmer Manufacturing & Supply is continuing its international and new market expansion. Jose Larrea will be instrumental in assisting with equipment development for these expansions," added Hartzell.

We’ve Got You Covered. For Another Year!

We genuinely believe in delivering quality with each piece of equipment that we make and take this seriously. We continuously improve both our processes and equipment to find new ways to improve. The bottom line is that our improvements will help increase your production day-in and day-out. As a result, we are implementing a new 2 Year Limited Warranty from your original date of purchase for all Palmer manufactured equipment. This is your assurance that should something malfunction—you’re covered. When you purchase from Palmer, you can count on being looked after…now for another year.

To view our updated 2 Year Limited Warranty, click here

The KLEIN PLUG FLO® System

The KLEIN PLUG FLO® system makes it possible to transport sand through pipelines with very little degradation. Lower air pressure, lack of fluidization air boosters and the KLEIN PLUG FLO® principle result in lower air consumption and therefore smaller dust collection system requirements at the receiver. The KLEIN PLUG FLO® system is especially suitable for granular, free flowing materials and offers lower wear and abrasion as well as minimum material separation or reaction during the transport phase.

Specifications

Operating rates up to 20 Tons per Hour per Unit

Benefits:

- No fluidization requirement eliminating product segregation

- No boosters required, system efficiency is increased and installation costs are lower

- Lower transport velocities - Only 40 to 450 feet per minute transport velocity resulting in less material degradation and drastically reducing pipe wear

- Very low air consumption per ton

- Standard Schedule 40 pipe, which lowers system installation and initial startup

- Minimal maintenance due to reduced wear and moving parts

- Standard operating sand temp up to 120°F

Simple Solutions That Work!™

Defect Prevention

Issue 13, Fall 2020

Our September 2020 edition is all about "Defect Prevention." This issue is devoted to this subject because it’s something that you can’t talk about enough. We hope you find the defect prevention ideas in this issue (that range from binders and the mixing process, melting, analysis, materials, and molding) techniques you can use today.

Click here to view this edition of Simple Solutions That Work!

Click here to view or download this edition of

Simple Solutions That Work as a PDF.

Have a solution you would like to share? Complete our form! All solutions that are selected for future publication will win $100 Palmer Bucks!

To subscribe to Simple Solutions That Work, click here: sign-up

Globe Hammers, Mixer Rebuild Kits, Aluminum Melt Quality Control Systems

Outils Pneumatiques GLOBE recently announced Palmer Manufacturing & Supply as the exclusive North & South American stocking distributor of GLOBE Knockout Hammers and replacement spare parts.

Click Here for more info

MIXER REBUILD KITS

Palmer provides two levels of rebuild kits to ensure you have the spare parts on hand to prevent any downtime or production disruption. In addition to specifying the wear parts, we also provide a substantial 15-20% discount when these kits are purchased versus purchasing these items individually. Our Rebuild Mixer Kits are available for M-50, M-100 and M-200, in two different levels: Level 1 Basic and Level 2 Deluxe. Please contact us for pricing or if rebuild kits are desired for other mixer sizes.

Click Here for more info

PAS5000

Melt Quality Control System

The Palmer PAS5000 represents a breakthrough in hydrogen porosity control of the aluminum melt and castings. With precise computerized control of the vacuum setting and quick automated measurements of sample density, the long-standing problem of operator variation is virtually eliminated.

Click Here for more info

2020 marks a major milestone for Palmer Manufacturing & Supply, as we celebrate our 45th anniversary.

Palmer started as a jobbing iron and aluminum foundry in 1975. Since that time, Palmer has grown into one of the world's most recognized names in foundry equipment manufacturing, with a worldwide representation network without whom we could never meet the needs of our customers. With a product line that grows as fast as it can be designed, Palmer now aggressively pursues global growth not only in the foundry industry, but in industrial markets as well.

"The last 45 years have given us plenty of reasons to celebrate," said Jack Palmer, President, Palmer Manufacturing & Supply. Through continuous investment and technology improvements, Palmer uses state-of the-art manufacturing processes to drive important leading-edge industry advancements that significantly increase productivity while reducing costs.

Palmer's roots as foundry men, causes us to look at things from the foundry perspective-which has led to innovations that are changing the way the foundry floor produces castings—to drastically increase productivity. Our introduction of the Universal Molding Machine is just one example of the most exciting innovations to hit the foundry floor in decades.

"We are proud to have played such a defining role in the advancements of mold, core, and material handling technologies, automation, and engineering as a 100% USA owned and operated company. And, the most important thing we are proud to be doing-is protecting American jobs.

Palmer's extensive library of Articles & Videos offers solutions you can use today.

Click on the article links below to read about Lowering Labor Costs with No-Bake Molding, Sand Reclamation Basics, Selecting the Right Sand Heater, and everything in between.

To see our products in action click on our Video & 3D Animation Library.

To see more Palmer Articles Library Click Here

To see more Palmer Animation Library Click Here

Whiting-Turner Contracting recently wrote this statement about how pleased they were with our installation of a molding system.

In 2020, Palmer completed a molding system installation for Whiting-Turner Contracting.

"It has certainly been a pleasure doing business with everyone at Palmer. Your engineering team was very responsive throughout the entire process. Brandon Myers was excellent at responding to all questions, concerns, and managing the installation and training. We also appreciated being able to come to the Palmer production facility to inspect the equipment. Additionally, we felt your technical sales staff did a great job in explaining the system prior to purchase.

Our system arrived in excellent condition and your team did a great job completing the installation despite the difficult environment. Most importantly, Palmer responded to punch list items in a timely manner. I wish to also highlight the professional and informative training provided by both Brandon Myers and Ken Strausbaugh with the owner and operators. We are pleased to also report that the Palmer mixer and equipment in the foundry are performing well."

Shelly Christman, Certified GGP, AM-ASCE

Project Manager

The Whiting-Turner Contracting Company

To see more Palmer system installations, please Click Here

Copyright © 2024 Palmer Manufacturing & Supply, Inc. | Terms and Conditions | Privacy Policy

Web published by Marketing Options, LLC.